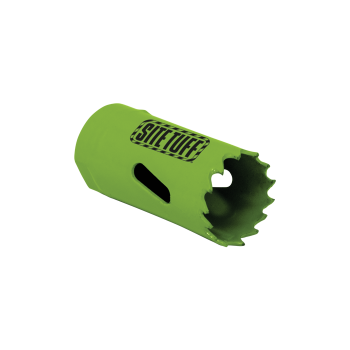

ST-HS

The Site Tuff range of HSS bi-metal hole saws are suitable for cutting through metal, plastic and wood. Their high resistance to heat ensures long life, and the 4/6 TPI variable pitch teeth provides fast, reliable cutting and aids swarf removal through thin and thick gauge materials. The versatility and quality of the Site Tuff bi-metal hole saws means that they are suitable for use by all trades and industries.

The Site Tuff range of HSS bi-metal hole saws are suitable for cutting through metal, plastic and wood. Their high resistance to heat ensures long life, and the 4/6 TPI variable pitch teeth provides fast, reliable cutting and aids swarf removal through thin and thick gauge materials. The versatility and quality of the Site Tuff bi-metal hole saws means that they are suitable for use by all trades and industries.

Product Details

| Part Number | Specifications |

|---|---|

GT40720 | 14 x 38mm |

GT40721 | 16 x 38mm |

GT40722 | 17 x 38mm |

GT40723 | 19 x 38mm |

GT40724 | 20 x 38mm |

GT40725 | 21 x 38mm |

GT40726 | 22 x 38mm |

GT40727 | 24 x 38mm |

GT40728 | 25 x 38mm |

GT40729 | 27 x 38mm |

GT40730 | 29 x 38mm |

GT40731 | 30 x 38mm |

GT40732 | 32 x 38mm |

GT40733 | 33 x 38mm |

GT40734 | 35 x 38mm |

GT40735 | 37 x 38mm |

GT40736 | 38 x 38mm |

GT40737 | 40 x 38mm |

GT40738 | 41 x 38mm |

GT40739 | 43 x 38mm |

GT40740 | 44 x 38mm |

GT40741 | 46 x 38mm |

GT40742 | 48 x 38mm |

GT40743 | 51 x 38mm |

GT40744 | 52 x 38mm |

GT40745 | 54 x 38mm |

GT40746 | 57 x 38mm |

GT40747 | 59 x 38mm |

GT40748 | 60 x 38mm |

GT40749 | 64 x 38mm |

GT40750 | 65 x 38mm |

GT40751 | 67 x 38mm |

GT40752 | 68 x 38mm |

GT40753 | 70 x 38mm |

GT40754 | 73 x 38mm |

GT40755 | 76 x 38mm |

GT40756 | 79 x 38mm |

GT40757 | 83 x 38mm |

GT40758 | 86 x 38mm |

GT40759 | 89 x 38mm |

GT40760 | 92 x 38mm |

GT40761 | 95 x 38mm |

GT40762 | 98 x 38mm |

GT40763 | 102 x 38mm |

GT40764 | 105 x 38mm |

GT40765 | 108 x 38mm |

GT40766 | 111 x 38mm |

GT40767 | 114 x 38mm |

GT40768 | 121 x 38mm |

GT40769 | 127 x 38mm |

GT40770 | 133 x 38mm |

GT40771 | 140 x 38mm |

GT40772 | 146 x 38mm |

GT40773 | 152 x 38mm |

GT40774 | 160 x 38mm |

GT40775 | 168 x 38mm |

GT40776 | 177 x 38mm |

GT40777 | 200 x 38mm |

GT40778 | 210 x 38mm |

Suitable for use on:

-

Aluminium

-

Cast Iron

-

Fibreglass

-

Laminated Products

-

Stainless Steel (Inox)

-

Steel Sections - Pipes and Bars

-

Plastic

-

Non-Ferrous Metals

-

Chipboard

-

Medium Density Fibreboard (MDF)

-

Plywood

-

Wood - Clean Hardwood

-

Wood - Clean Softwood

-

Brass

-

Copper

-

Plasterboard

Machine Suitability

-

Cordless Drill

-

Corded Drill

-

Electric Drill

Usage Advice:

-

Always wear the appropriate PPE, including eye protection and gloves.

-

Ensure the material being drilled is secure and stable, before drilling.

-

Observe the recommended drilling speeds, to ensure the hole saws optimum performance and life expectancy.

-

Use An appropriate cutting fluid on metal products to prolong the life of your hole saw

-

Avoid overheating the hole saw, as excessive heat build-up may reduce its life. Allowing the hole saw to cool after a hole is advantageous.

-

Keep the hole saw straight throughout the drilling process and avoid using the trigger lock, to reduce the risk of snagging and injury

-

ALWAYS use the drill’s side handle for greater control and safer drilling (The machine’s safety clutch will not function without complete control of the machine)

More products in the Bi Metal Hole Saws range

Registered Number: 02965789 England

Registered Address: The Quay, 30 Channel Way, Ocean Village, Southampton, SO14 3TG

Trading Address: Unit 10 The Boulevard, Altira Park, Herne Bay, Kent, CT6 6GZ, UK

Opening Hours

Mon-Fri: 8am - 5pm

Sat-Sun: Closed

Contact

Tel: +44 (0)1227 711555

This email address is being protected from spambots. You need JavaScript enabled to view it.

Opening Hours

Mon-Fri: 8am - 5pm

Sat-Sun: Closed

Contact

Tel: +44 (0)1227 711555

This email address is being protected from spambots. You need JavaScript enabled to view it. This email address is being protected from spambots. You need JavaScript enabled to view it.

About Us

Premier Diamond Products is a leading specialist supplier of top quality diamond blades, diamond core drills, diamond grinders

read more...

©

Premier Diamond Products. All rights reserved.

Privacy Policy

Website and Design by Lemon Creative