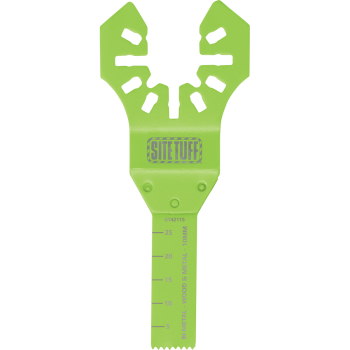

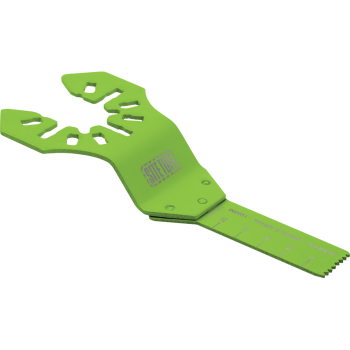

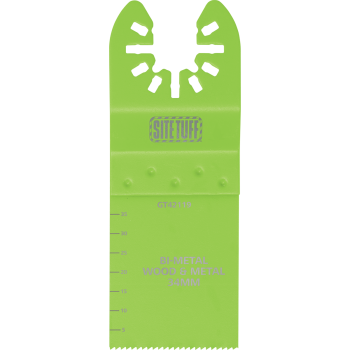

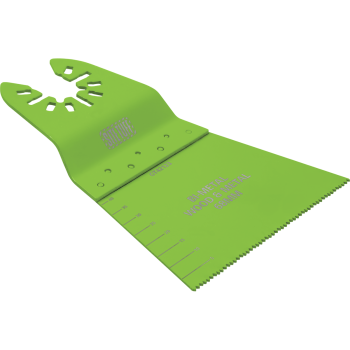

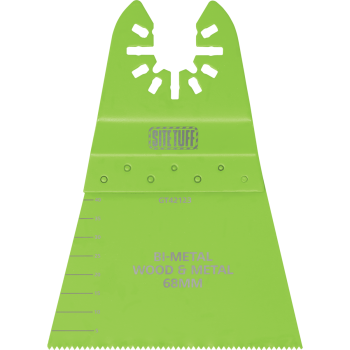

ST-MTB-BIM

The combination of the ST-MT-BIM’s Bi-Metal, High Carbon Steel Body (HCS) and High Speed Steel (HSS) tooth strip, ensures a lasting sharpness with the appropriate flexibility whether you are plunge cutting, flush cutting and or simply trimming materials such as wood, wood with nails, thin gauge soft metals, non-ferrous metals and plastics.

The combination of the ST-MT-BIM’s Bi-Metal, High Carbon Steel Body (HCS) and High Speed Steel (HSS) tooth strip, ensures a lasting sharpness with the appropriate flexibility whether you are plunge cutting, flush cutting and or simply trimming materials such as wood, wood with nails, thin gauge soft metals, non-ferrous metals and plastics.

Product Details

| Part Number | Specifications |

|---|---|

GT42115 | 10mm x 30mm - 3 Pack - Bi-Metal (BIM) - Wood & Metal |

GT42117 | 34mm x 40mm - 3 Pack - Bi-Metal (BIM) - Wood & Metal |

GT42119 | 34mm x 40mm - 10 Pack - Bi-Metal (BIM) - Wood & Metal |

GT42121 | 44mm x 40mm - 3 Pack - Bi-Metal (BIM) - Wood & Metal |

GT42123 | 68mm x 40mm - 3 Pack - Bi-Metal (BIM) - Wood & Metal |

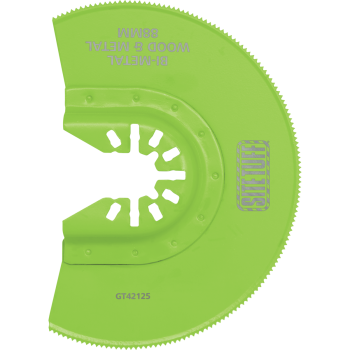

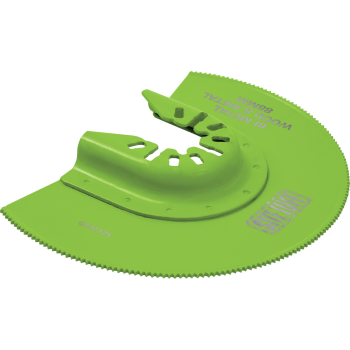

GT42125 | 88mm - Radial - 3 Pack - Bi-Metal (BIM) - Wood & Metal |

Suitable for use on:

-

Aluminium

-

Laminated Products

-

Plastic

-

Chipboard

-

Medium Density Fibreboard (MDF)

-

Nail Embedded Wood

-

Plywood

-

Wood - Clean Hardwood

-

Wood - Clean Softwood

-

Plasterboard

-

Non Ferrous Metals - opper, Zinc, Lead

-

Melamine

-

Oriented Starnd Board (OSB)

-

Soft Screws & Nails (Not Stainless Steel)

-

Tile Grout & Adhesive Removal

Machine Suitability

-

Multi Tool

Usage Advice:

-

Always wear the appropriate PPE

-

Make sure that the blade is the correct fi tting for your machine

-

Ensure you select the correct blade for your task

-

Avoid using excess pressure when cutting. Trying to force the blade to cut will reduce the speed of cut and overheat the blade

-

Excessive heat build-up can damage the blade. Using the full width of the blade when cutting can help to dissipate the heat, and prolong the life of the blade

-

When cutting round objects such as waste pipe, select a wider blade than required to reduce the risk of the blade slipping during the cut

-

To achieve clean, straight cuts, when plunge cutting, use a straight edge to support and guide the blade. Use a slight rocking motion to reduce surface resistance and increase the speed of cut

-

When cutting curves, the semi-circular radial blades allow for closer control to follow the cut line

More products in the Multi-Tool Blades range

Registered Number: 02965789 England

Registered Address: The Quay, 30 Channel Way, Ocean Village, Southampton, SO14 3TG

Trading Address: Unit 10 The Boulevard, Altira Park, Herne Bay, Kent, CT6 6GZ, UK

Opening Hours

Mon-Fri: 8am - 5pm

Sat-Sun: Closed

Contact

Tel: +44 (0)1227 711555

This email address is being protected from spambots. You need JavaScript enabled to view it.

Opening Hours

Mon-Fri: 8am - 5pm

Sat-Sun: Closed

Contact

Tel: +44 (0)1227 711555

This email address is being protected from spambots. You need JavaScript enabled to view it. This email address is being protected from spambots. You need JavaScript enabled to view it.

About Us

Premier Diamond Products is a leading specialist supplier of top quality diamond blades, diamond core drills, diamond grinders

read more...

©

Premier Diamond Products. All rights reserved.

Privacy Policy

Website and Design by Lemon Creative